Installation and Underlay

Article provided by Godfrey Hirst

All carpets must be installed in accordance with AS/NZS 2455.1:2007

“Textile floor coverings – Installation Practice – General” standard and the Godfrey Hirst installation recommendations as set out on the following pages.

Installers – Insist on trained professional tradesmen to install your carpet.

Check first – before making any cut from a roll, ensure your installer examines the carpet and checks for length, quality, pattern, colour and dyelot. Once a roll has been cut, claims will generally not be accepted for these issues.

Power Stretching

All carpets must be power stretched. Bubbling

and wrinkling may occur if carpet is not adequately

power stretched during installation.

Seams

Seam adhesive (sealer) must be used for all seams,

width wise and length wise in all installations. Use

a solvent based seam seal adhesive on direct glue

down applications. On conventional installations

use a latex based seam seal adhesive. If the seams

are not permanently bonded together the carpet

may unravel and begin to break down at the edges,

causing premature wear. Poorly bonded seams are

not the responsibility of Godfrey Hirst.

Stairs

On stairways the pile should sweep down. A little

hidden extra carpet should be folded back at the

top and bottom of stairs so as the edges of the

tread are worn down, the carpet can be moved

to hide the wear point. Purchasing extra carpet

to replace carpet on stairways is recommended.

Wrinkling (or Rucking)

Wrinkling may occur after installation. It can

be caused by excessive humidity, inadequate

underlay or not using the recommended installation

procedures, in particular failing to use a power

stretcher. A competent installer can usually correct

this problem.

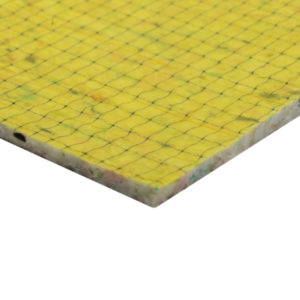

Underlay

Underlay and carpet are designed to work together

as a complete flooring system. Generally, a quality

underlay will extend the life of your carpet while

giving better resilience and comfort.

Ask your retailer to match a quality underlay

(compliant with the appropriate classification for

the intended use/application as per AS4288 i.e.

light residential, general, luxury, commercial or

heavy commercial) with the quality and proposed

use of your carpet.

Pile Direction

Carpet pile should run in the same direction

throughout the installation, sweeping towards

the main entrance where possible.

Seams and cross joins in the wrong place can

spoil the appearance of your carpet and lead

to premature wear. Generally, seams should

run in the same direction as most foot traffic.

Seams should be avoided in high traffic areas

and kept as far away from windows as possible,

to avoid light falling across the seam making it

appear more obvious.

Ask the installer where they plan to place seams

and cross joins before the carpet is cut.